Thin Film Nano-composite Membrane Fabrication for Carbon Dioxide Capture from Flue Gas

In view of all these difficulties, large membrane areas are required to handle the huge gas flow and membranes with high permeability is essential to boost the productivity. Until membranes with such characteristics are developed, the implementation of membrane systems in CO2 separation from flue gas seems unlikely.

Mixed-matrix membranes combining the benefits of both polymeric and inorganic materials open a new possibility for membrane gas separation technology in CO2 capture from flue gas. The use of two materials with different permeability and selectivity provides the possibility to better design a membrane for CO2 capture, allowing the synergistic combination of polymer’s easy processability and superior gas separation performance of inorganic materials. Furthermore the addition of inorganic materials in a polymer matrix offers enhanced physical, thermal and mechanical properties for aggressive environments and represents a way to stabilize the polymeric membranes against change in permselectivity with temperature.

The conventional blending technique is the most commonly used approach to prepare the mixed-matrix membrane. One of the major issues with the blending technique is the difficulty to increase the inorganic filler loadings in the mixed-matrix membranes. With low particle loadings, the gas transport behaviour in the membrane structure will still be dominated by the polymer matrix rather than the inorganic fillers. With such concern, a novel layer-by-layer deposition procedure is developed in our lab in order to significantly increase the particle loading without the sacrifice of separation performance.

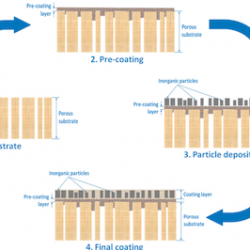

The layer-by-layer deposition procedure involves three steps:

- PDMS pre-coating on the substrate: Introducing such a gutter layer between substrate and coating layer is based on two considerations, i) prevent the diluted polymer solution penetrating into the porous substrate, and ii) smoothen the surface of the substrate which facilitates the formation of ultra-thin final coating layer.

- Particle deposition:Different types of metal organic frameworks(MOFs)are chosen in this work as the inorganic fillers since the presence of these particles provides highly permeable yet selective channels for gas molecules to permeate through. The deposition of the particles on the substrate was carefully controlled to ensure the substrate is completely covered with a mono-layer of the MOFs.

- Final coating with block co-polymer: The main purpose of the final polymer coating layer is to seal all the defects between the deposited particles. In terms of the selection of the polymer materials, a CO<sub>2</sub>-philic polymer material can be chosen to further boost the CO2 permeability. With such concern, PEBAX® 1657 is chosen in this work. Furthermore the use of PEBAX® 1657, a block co-polymer, can also bring another benefit: its unique structure can suppress the adhesion issues between polymers and particles.

Separation of CO2 from coal-fired power plant flue gas presents a huge challenge for membrane separation systems, because of;

- low concentration of CO2 in feed stream,

- low feed gas pressure

- enormous gas flow need to be processed.

Research Team: Vicki Chen

Guangxi Dong