MOF based highly efficient gas separation membrane

Molecular sieving membranes are promising candidates for applications that require highly selective permeation, such as gas separation, organic solvent nanofiltration, water treatment and chemical sensors. The key to their successful implementation is the synthesis of a thin but defect-free selective layer. Due to their large porosity, molecule-dimensional pore size and good stability, metal-organic frameworks (MOFs) have been extensively studied for their potential as molecular sieving membranes, mostly by coating MOFs onto inorganic porous supports. However, such membranes are considerably hampered by their complex processing, high cost, rigidity, and brittleness. On the other hand, formation of thin, continuous MOFs onto porous polymeric supports has been difficult due to lack of sufficient heterogeneous nucleation sites and adhesion. Chemical modifications on the polymer surface or interfacial precipitation have been used to grow MOFs within porous substrates or as isolated crystals. Recently, atomic layer deposition has been applied to grow aggregates of MOF crystals directly on solid polymeric fibers for gas adsorption. However a facile approach to grow a thin, continuous MOF films directly from the synthesis solution has not been available for porous flexible substrates such as polymeric membranes. Theoretically, due to the reversible MOF structure changes under moderate mechanical loading, the MOF layers can exhibit a degree of flexibility. However, this has yet to be demonstrated in continuous, macroscopic films as semipermeable membranes. To achieve this, two major hurdles need to be considered: good adhesion of MOFs on flexible, porous support and formation of a uniform, coherent film.

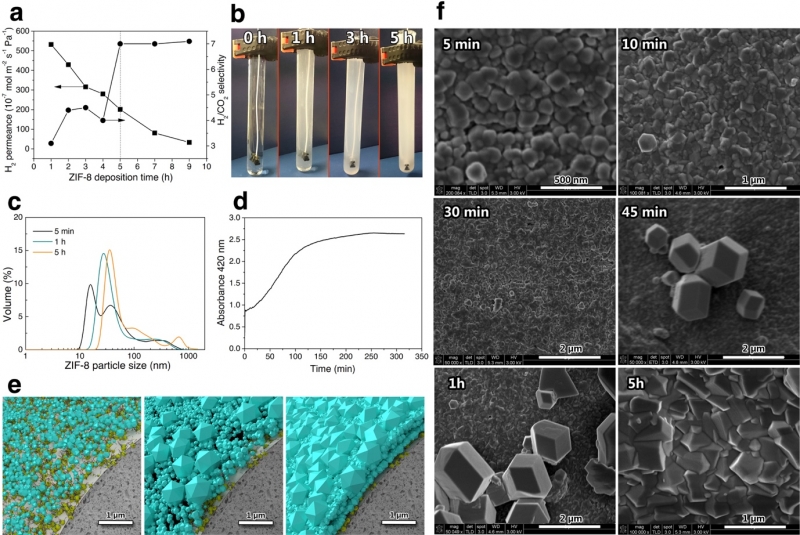

Our group has developed a simple low temperature hydrothermal sol-gel coating technique to deposit an ultrathin layer of TiO2 coating with controllable architecture on various polymer supports. The functionalization of the coating layer has been explored for anti-fouling properties, enzyme immobilization and super-hydrophobicity. We postulated that the titania layer’s large surface area, nano-roughness, and hydrophilicity will promote heterogeneous crystallization on the support. Hence, we explored MOF (specifically, ZIF-8) formation on APTES functionalized TiO2 coated 0.05 micron pore size hollow fiber PVDF membranes. The coherent ZIF-8 layer was surprisingly flexible and well adhered to the support such that the composite membrane could sustain bending and elongation. The membranes exhibited molecular sieving behaviour, close to the theoretical ZIF-8 permeability, with hydrogen permeances up to 201 × 10-7 mol m-2 s-1 Pa-1 (60,000 GPU) and H2/CO2 selectivity of 7. This approach offers significant opportunities to exploit the unique properties of MOFs in the fabrication of separation and sensing devices.

Gradual deposition of ZIF-8 onto the support surface. A) H2 permeance and H2/CO2 selectivity of membranes with different ZIF-8 deposition time. B) Photograph of the ZIF-8 deposition process. C) Change of the ZIF-8 crystal size within the deposition solution. D) Turbidity of the suspension liquid during the deposition process. E) Schematic diagram of the ZIF-8 deposition process. F) Surface SEM images of the ZIF-8 deposition process with different reaction time. Quick amorphization occurred when exposing the nano-scale ZIF-8 to the electron beam.

Research team: Prof. Vicki Chen

Dr. Jingwei Hou

Putu Sutrisna (PhD student)

Publications

Hou, J., Sutrisna, P.D., Zhang, Y. and Chen, V., 2016. Formation of Ultrathin, Continuous Metal–Organic Framework Membranes on Flexible Polymer Substrates. Angewandte Chemie.