Membrane Manufacturing

Membrane manufacturing can be technically challenging and in the last few years the Membrane Centre has established a new laboratory for purpose of developing new membrane material for gases and liquid. Facilities at the centre include:

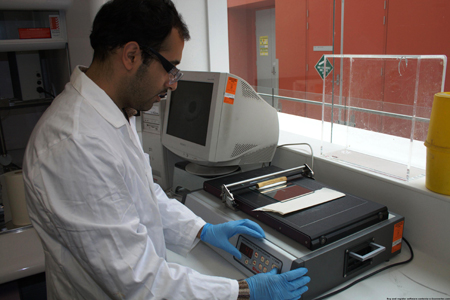

MEMBRANE CASTING

To produce membranes by the phase inversion method, it is necessary to cast consistent films of a known, uniform thickness that can subsequently be immersed in coagulation bath and dried or cured by the appropriate method. Historically, hand operated applicators using casting knife have been used to apply such films, but it is difficult to accurately judge the traverse speed of the applicator and also maintain a constant speed, resulting in an uneven film thickness and variation in membrane performances. The Sheen 1133N Automatic Film Applicator provides a motorised method of driving a range of film applicators. The speed range of this instrument is from 50-500 mm/s.

HOLLOW FIBRE SPINNING

The Centre’s custom built polymeric hollow fibre membrane fabrication unit uses a dry-jet, wet spinning technique, where the dope and bore fluid are co-extruded from the spinneret into the air gap with ambient conditions. Once passing through the air gap, the nascent fibres are immersed into a coagulation bath filled with tap water at room temperature. After passing over one wheel-guide, fibres are collected on a take-up drum with a perimeter of 1 meter and ready for further treatments.

NANOFIBRE SPINNING UNIT

This Centre’s new ForceSpinning Cyclone L-1000M/D can be used for making nanofibers from a wide range of materials.

the nano-fibers The force spinning unit replaces the electrical field used in electrospinning with centrifugal forces, which as a result eliminates the need for high electric fields and dielectric solutions. So the selection of materials that can be spun is not limited to conductive materials. The system can control spinner speed and temperature, and the process consists of depositing material either as a solution or as granular solids that are melted in the spinneret and then spun to make

.